Full-automatic intelligent carton cutting machine

PACKSIZE Booth No.: 4B66

Full-automatic intelligent carton cutting machine adopts continuous corrugated paperboard as raw material, and can realize the online cutting of cartons fitting with article sizes and produce cartons of any models, thus reducing purchase, management, manpower, warehousing and transport costs and achieving energy conservation and emission reduction. Each year it can save 40% of packaging materials. Relying on a seamless connection with corporate production management system, it can also realize the informationized management of packaging.

INTELIS JIVARO

SAVOYE Booth No.: 4B118

INTELIS JIVARO can adjust sealing height according to the volumes of actual articles without dispensing extra fillers, thus minimizing shipment size and maximizing loading rate (by as high as 100%). With the aid of automatic sealing and capping, parcels have a more steady geometric structure, and paperboard consumption is reduced by 7%; by saving the adhesive tape application link, it has practiced the concepts of greenness and environment-friendliness, and reduced the breakage rate during transport to the lowest level. Each INTELIS JIVARO can package 14 cartons at the maximum each minute, which greatly saves manpower.

I Pack automatic carton packaging equipment

SealedAir Booth No.: 4B120

I-Pack® height-adjustable automatic cartoning system can fully integrate and effectively improve your packaging production line, more efficiently package your products, and guarantee the full satisfaction of your customers.

1.Sustainable solution: 100% corrugated paper packaging, “roadside” recycling, and sustainable development/reduced carbon emission

2.Tamper-proofing: packaging with hot melt adhesive, firm and tight

3.Easy to open: built-in tear tape, opened with a gentle pull

4.Convenient sales return: use of adhesive tape available in the tear tape region

XTB series full-automatic intelligent sleeve-type packaging equipment

ZHONGYA Booth No.: 4B112

1.Increased carton packaging and printing area, eye-catching brand and shelf display

2.Automatic processing, one-piece packaging, and increased product sales

3.Highly portable

In 2019, Asia-China Packaging joined hands with BINGXIN Paper Packaging to launch a full-automatic intelligent octagonal carton packaging machine, which not only reduces corrugated paper consumption but also offers more display angles. It has become the first choice for the brand owners of fast moving consumer goods (food, beverage, daily chemicals and so forth) in developing promotional packages and direct shipment packages.

Magnetic-suspension intelligent wrapping machine

ZHONGYA Booth No.: 4B112

Magnetic suspension technique is one of the highlights of intelligent packaging machine, which has embedded magnetic suspension rail and an intelligent trailer used for carrying parcels at a maximum speed of 5 m/s. The intelligent carton selection solution provided by it has conducted important innovations and practice in the field of energy conservation and environmental protection. According to the calculation results after use by customers, the intelligent packaging machine has a packaging efficiency of as high as 1,000 parcels/h, an improvement of ten times on the basis of traditional packaging operations.

Intelligent high-speed wrapping machine for express delivery

GURKI Booth No.: 4B136

With a speed of 1,200 parcels/h, it has renewed the record of packaging speed in the field of e-commerce logistics. In addition, it can also provide 0.5 s automatic top-speed code scanning, automatic weighing, error elimination, automatic packaging, automatic express sheet attaching, and other integrated solutions. Meanwhile, it can also dock with mainstream ERP system and WMS system based on customer demands, and offer integrated plastic film packaging and shipment solutions for customers.

Bubble film wrapping machine

King Sunlight Booth No.:4B83

The machine can automatically deliver goods to the bag sealing mechanism, and use a horizontal sealing knife for bubble bag sealing & cutting, real-time printing with labeling machine, and final label checking, followed by output sorting after sealing & cutting on both sides. The real-time monitoring system of the whole packaging process is designed with an error alarm mechanism.

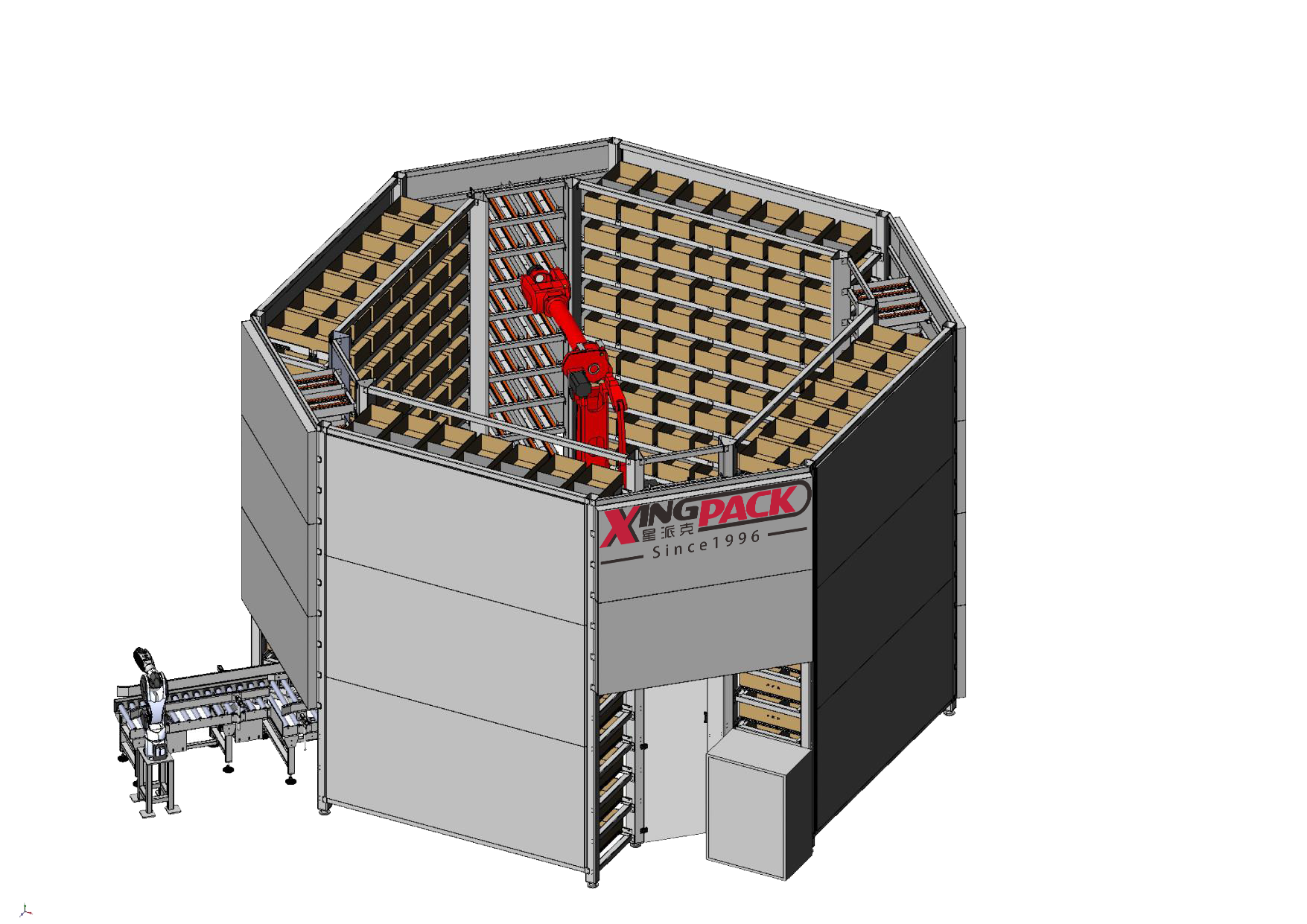

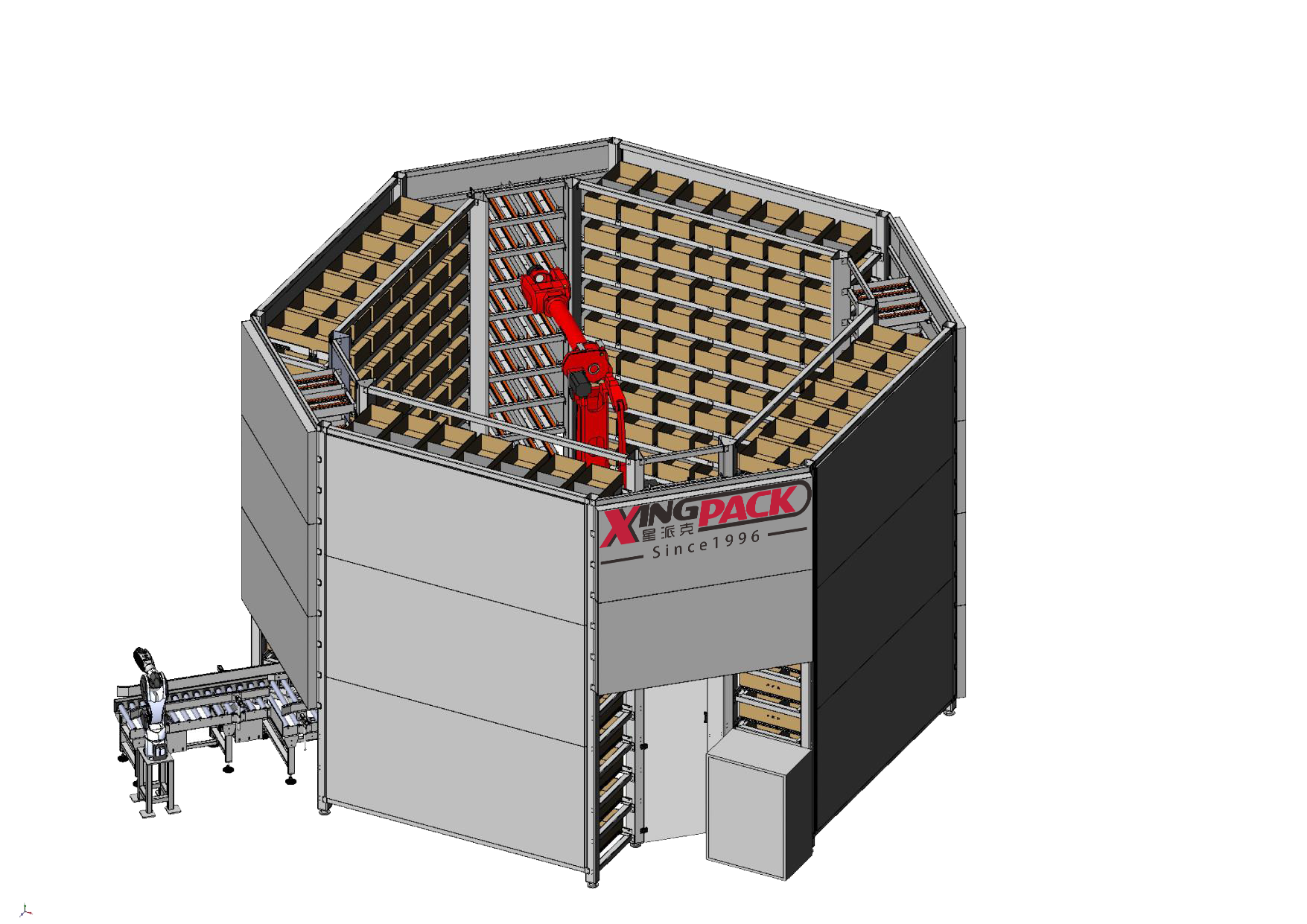

Intelligent warehousing system for cubic warehouse

XING PACK Booth No.:4B95

According to different warehouse models, the robot can use either double gripper or single gripper, with a speed of one carbon (pair) every 5 s. One warehouse can be arranged with 1,100 storage locations. The robot has a maximum arms-pan of 3.5 m, a rotary angle of 355°, and a maximum loading capacity of 50 kg.

Extended functions

1.Based on actual service requirements, the sizes of storage locations can be adjusted accordinglywithout unified installation.

2.Unstacking and stacking systems are applicable to the unstacking, stacking, warehousing and transfer of cartons in various industries.

3.AGV trolleys are used for transfer support within factories.

EVO carton cutting machine

Panotec HK Limited Booth No.:4B122

It can be used to produce cartons of different sizes and models, with both reliability and speed guaranteed. In terms of time, space, and, most importantly, cost, it enjoys real advantages, including disposing of unrecoverable fillers, and customizing cartons without wasting raw materials.

Hot melt adhesive system

ROBATECH Booth No.:4B65

Cylinderless hot melt adhesive system is designed for melting and pumping granular thermoplastic

adhesives. Melting glues on demand slowly, the system is applicable to high and low glue consumption occasions. By virtue of the fast heating characteristic of Concept Stream, it can heat the glue to 160℃ within only 16 min, and be used for efficient production; it is also designed with a flow meter for monitoring variation in glue consumption. In addition, the glue melting system can realize a glue melting performance of 8 kg/h within the minimum space.

Intelligent bubble bag wrapping machine for express delivery

Guangzhou Q-Packing Automation Technology Co., Ltd./Tianjin SPIN Technologies

Booth No.:4B138

This machine is especially designed for the online shipment link of e-commerce, and offers integrated solutions like goods code scanning, one express sheet for one article, one express sheet for several articles, automatic backing adhesive removal, automatic capping, automatic express sheet printing, automatic express sheet attaching, etc. Based on customer demands, it can also automatically dock with e-commerce orders and corporate ERP and WMS systems, and offer integrated bubble bag packaging and shipment solutions for customers.

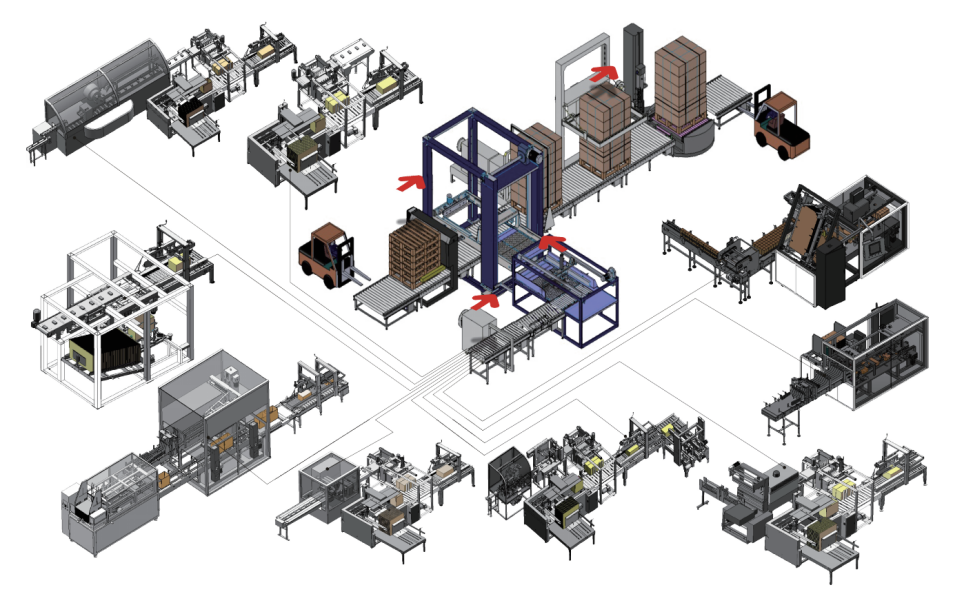

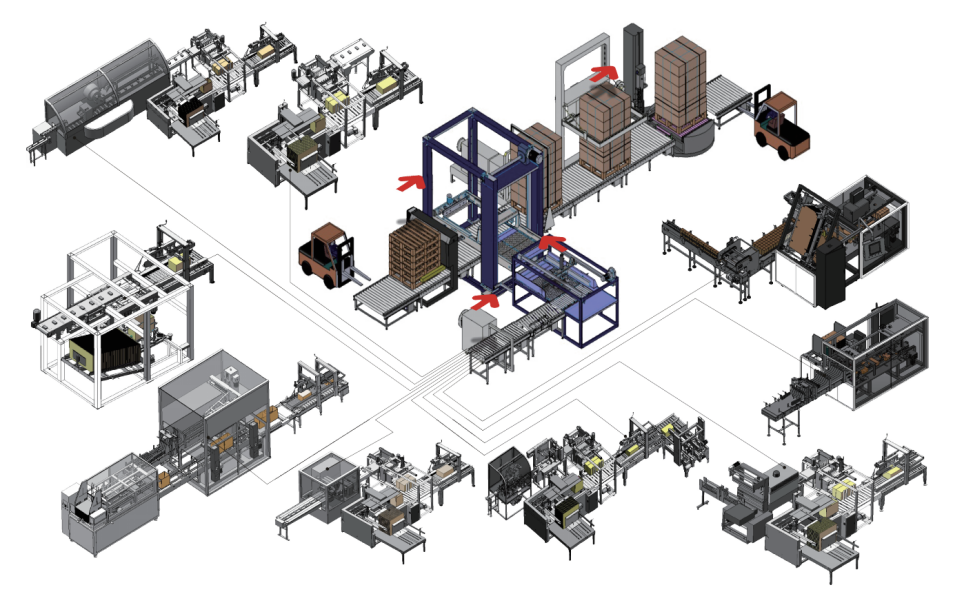

Intelligent packaging production line for e-commerce logistics

Youngsun Booth No.:4B81

Youngsun has always focused on the R&D design, manufacture, installation, debugging and technical service of packaging equipment and supporting packaging materials, and offers packaging equipment solutions relying on its technical strength. In terms of technical level, Youngsun is leading the country in the fields of intelligent dairy production system, intelligent beer & beverage production system, intelligent robot packaging system, S6 intelligent system platform, carton molding machine, paper packaging machine, full-automatic cartoning machine, boxing machine, envelope thermoshrinking machine, full-automatic cartoning sealing machine, packing & unpacking machine, full-automatic strapping machine, semi-automatic strapping machine, full-automatic stacking machine, self-propelled winding machine, DIP-YP-40000 production line, intelligent food & beverage packaging production line, and intelligent packaging production line.

The brands of the company enjoys certain global influence, and its products are sold to more than 50 countries and regions worldwide, including the US, Germany, South Korea, Italy, etc.

Automatic bagging, printing and �labeling machine for e-commerce and express delivery

HUALIAN Booth No.:4B116

This machine is a full-automatic machine integrating bagging, sealing & cutting, printing, and labeling. After using a thin film for packaging, it then uses a full-automatic printing & labeling system to attach an express sheet with real-time information on the outside of the thin film.

Wrapping robot 305S

LEADOIN Booth No.:4A19

The Packing Robot 305S is an integrated inspection, printing, labeling and sealing integrated solution that enables intelligent scanning and seamlessly docks mainstream ERP/WMS orders to eliminate missed errors. Real-time printing of face information, automatic labeling, and automatic sealing technology make the sealing tidy and improve the packaging quality. It is also packaged in a PE roll bag to prevent damage and theft of the packaged items, saving resources and protecting the environment.

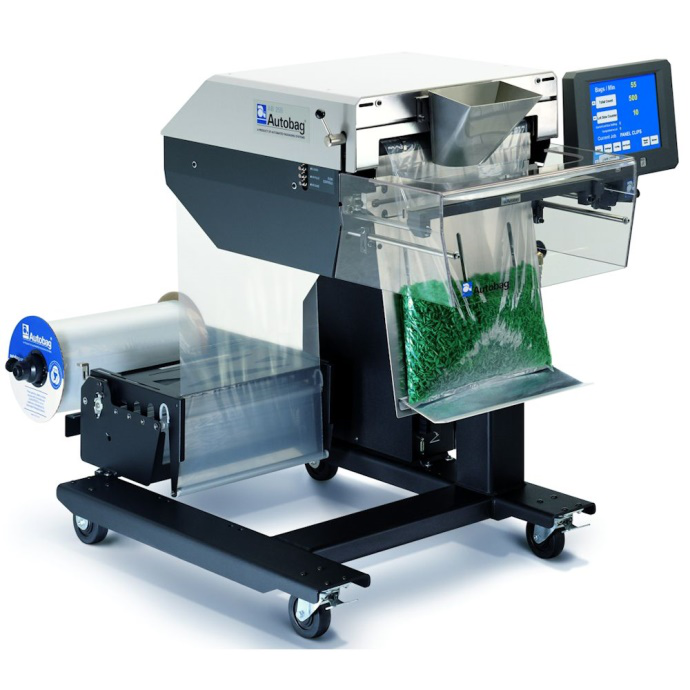

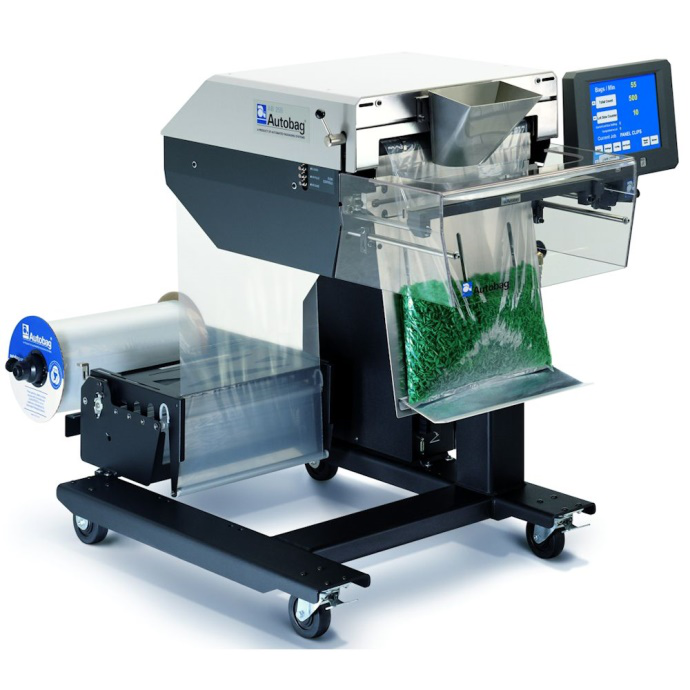

Autobag AB255 horizontal model

Dehao Booth No.:4A71

Autobag AB255 horizontal model is a pioneer in the field of big bag packaging. As an automatic manual bag sealing machine, it is designed to meet the specific demands of big bag packaging, and can realize a packaging speed of 55 bags/min. In addition, it is reliable, flexible, and easy to operate, and can maximally increase production efficiency.

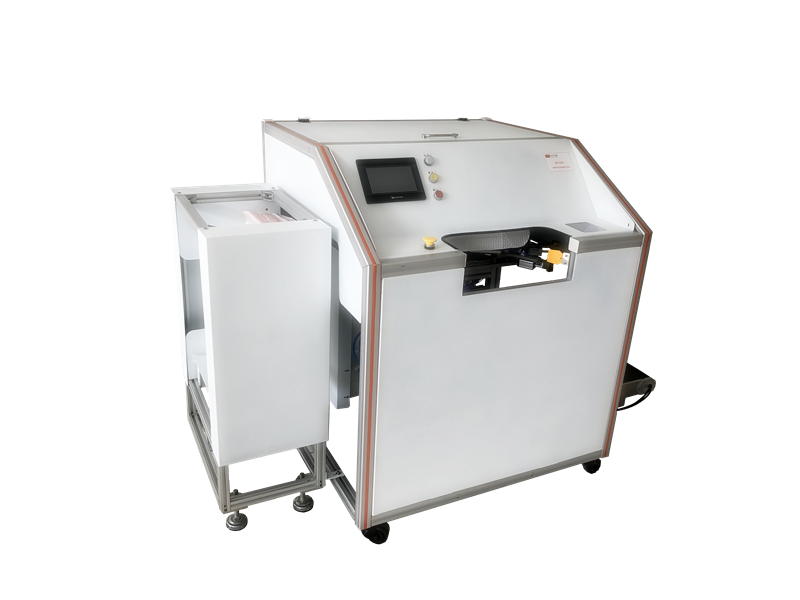

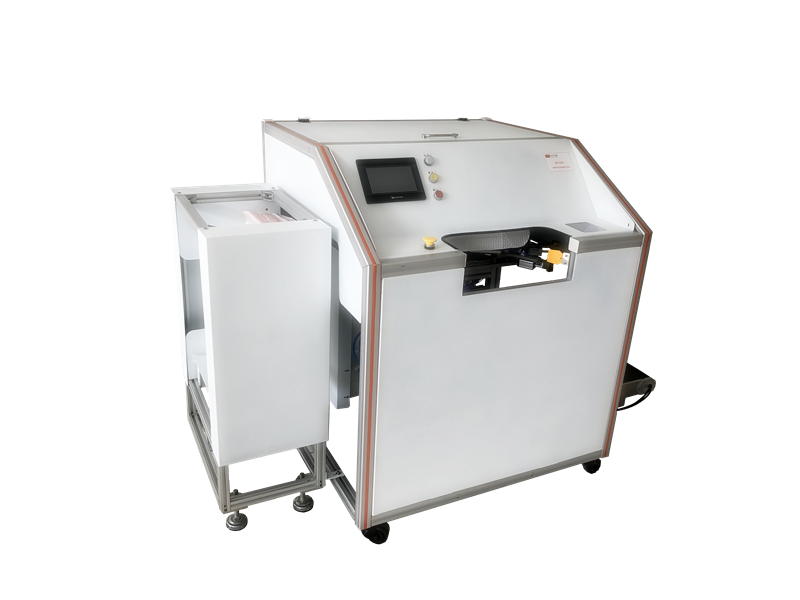

Mini cartoning sealing machine for e-commerce

RING PACK Booth No.:4A38

Adopting a standalone model and up-bottom “linear” automatic sealing, it applies to cartons of different specifications within the same period of time. In terms of transmission mode, it adopts bilateral belt drive, and is applicable to lighter cartons. Within the specifications of cartons, it can automatically adjust the height and width of cartons of different specifications; when it comes to cartons of different sizes, it can conduct automatic calibration to provide proper sealing.

“Minions” winding machine

JAGPACK Booth No.:4B24

1.It can create trays or articles of any shape, weight or size through automatic winding within 60 s.

2.Cargo packaging height can reach as high as 2,400 mm-2,100 mm.

3.It uses a dynamic pre-stretched film framework, and can realize a rotary angle of 350%.

4.Adopting a rapid film penetration design, it can quickly and easily complete roller replacement.

* The list above is not in any particular order.

Find more innovative technologies

At ECPAKLOG2019

沪公网安备 31010702006282号

沪公网安备 31010702006282号